Profile of Patents

Layout of RTI

RTI started its

global patents application quite early; however, it has not been

very keen in pursuing the patents application among all those

years. It seems that the company has taken no account of

Chinese market as all of its patents in China were invalid. By Sep. 2014, there

were 33 patents all together regarded to the field of titanium alloy for RTI.

As we can see in the Fig. 3, RTI applied its first patent as early as 1966, but

the curve of the application did not turn to be smooth and steady until the

year of 1987.The period

ranged from the end of 1970s to the end of 1980s was a vacancy for patents

layout, and the company didn’t seem very

active in the patents application, except in

the year of 2004. The inactive layout strategy resulted in a low quantity

in patents application.

Fig.3 Global

Patents Application of RTI over the Years

In terms of technology

layout of patents application, RTI paid

more attention to the patents regarded to titanium alloy, titanium materials,

and the processing techniques of titanium. Among the patents layout of titanium

alloy, the company placed more emphasis on the titanium processing techniques

as there were seven patents applications in terms of the field of casting,

especially the continuous casting technique. In terms of the application areas,

RTI has not only laid its patents layout in the field of aviation, but also in

the field of sports apparatus, for example, the golf clubs. It’s worth noting

that RTI has placed no patents layout yet in the field of titanium sponge that

belongs to the upstream of the industry.

2. Strategies and Characteristics of RTI Patents Layout

RTI adopted

sugar-coated patents layout together with the roadblock-pattern, so as to

improve the degree of difficulty for competitors entering the technical fields.

Take patents

layout of continuous casting technique as an example, RTI put forward several

peripheral technologies regarded to continuous casting methods including the

preheating methods for continuous casting, temperature control methods and

devices in the continuous casting furnace, and the sealing casting methods in

the continuous casting devices within three years. It has formed a

patents network consisting of core patents and peripheral patents, and thus to

effectively improve the difficulty for competitors entering the field of continuous

casting.

Similarly, the

hot forming technology of titanium bar has also been formed a

small-scale roadblock-pattern layout of patents. RTI has

successfully extended the network of continuous casting patents to the hot

forming technology of titanium bar through two patents of the continuous

casting techniques and equipment of the long-sized casting.

In the future,

RTI would still concern the constructing of core patents complex including the

processing techniques of titanium alloy of midstream industry chain, continuous

casting techniques, and the titanium bar processing techniques.

There’s a wide

range of processing techniques applied by RTI. In 1990s, the company proposed

de-oxidation

method for fire-resistant materials and the method of removing oxide layer on

titanium ingoting; in 2002, it

proposed the method for melting and casting titanium alloy and the method for

melting the titanium alloy through plasma arc and electron beam; after 2006,

RTI has formed a complete set of patents complex concerned continuous casting

techniques on the basis of the patents of US2006102314 and US2006254746, and it

further proposed the continuous casting techniques and equipment of long-sized

casting represented by titanium bar with the aid of hot forming technology of

titanium bar of 2007.

With the help

of commercial acquisitions and asset sale, RTI adjusted the patent portfolio

and completed the patents screen circle of the corresponding technologies. The

company expanded the production and improving the processing ability by the

means of acquisition.

At the same

time, it also implemented strategic adjustment through asset sale. Since 1997,

RTI has acquired Claro Precision Engineering of Canada and Remmele Engeenng of

Aeromet of the UK and marched to the fields of downstream aviation, national

defense, and medical devices with the goal of turning to be an independent

producer of titanium bar. Obviously, acquisition has been an important way for

RTI to consolidate its position as a leading

enterprise.

RTI

established six companies all together through acquisition and joint-venturing,

among which the patents of Dynamet Technology and Osbom has effectively

perfected the patents layout of RTI. Dynamet applied three patents in the field

of titanium-tungsten alloy and thus constituted a complex with the core

technology of powder metallurgy processing of titanium-tungsten alloy. Besides,

Dynamet further proposed patents of the manufacturing methods of the

fine-grained titanium alloy and oxygen-enriched TC4 alloy. With the help of the

acquisition on June 2014, RTI has successfully involved the patents concerned

titanium alloy, including the manufacturing technique of titanium-tungsten

alloy, into its patents layout, which to some degree has made up the patents

vacancy in the field of titanium alloy.

Analysis on Patents

Layout of ATI

1. Profile of Patents Layout of ATI

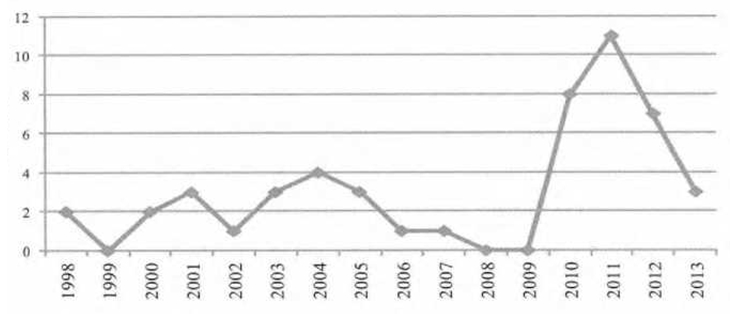

Although ATI started its global patents application

quite late, it has been very active in the patents application. It was not

until 1998 ATI applied its first patent, which was quite late compared with the

other two magnates. With the commissioning of its titanium sponge factory in

Raleigh, the upstream supply channel of ATI has been guaranteed, the patents application

of ATI has hugely increased since 2010. In 2011, the annually applications

mounted to the record high of 11. The active attitude of ATI on patents application

helped the company to achieve a Corner Overtaking in the area of patents. By

September 2014, ATI applied 49 patents in the field of global titanium alloy

all together (Fig. 4).

Fig. 4 Global

Patents Application of ATI over the Years

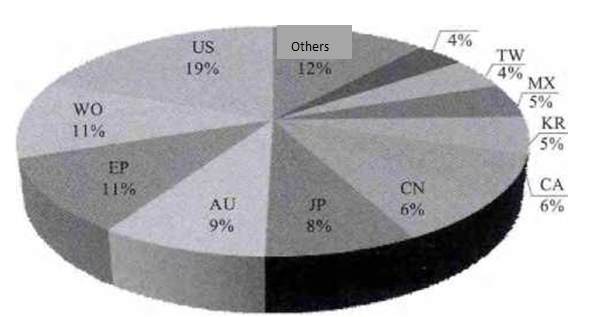

The patents

layout of ATI is characterized by its wide target area and uniform market

distribution. As we can see from Fig. 5, most of the patents layout of ATI distributed

in the US, Europe, Australia, Japan, China, Canada, and South Korea. And in

terms of the quantity of patents application, apart from the US, it was similar

among the countries and areas. And a large proportion of the application of ATI

was applied in the way of PCT.

It’s worth

mentioning that most of the applications of ATI in China have already been

audited but yet to wind up. The applications in the authorization and

maintenance status still have 7 to 10 years to expire, which means ATI is still

in the exploration stage in developing Chinese market.

Fig. 5 Distribution

of ATI Global Patents Application

2. Strategies and Characteristics of ATI Patents

Layout

With the

strong independence among every single patent and few researches on sustaining

technologies, the network of the patents layout of ATI has not fully

established yet. Although ATI ranked the first in terms of the quantity of the patent applications among all

three magnates, the company has not established a complete network of patents

layout yet.

Similar to

Timet and RTI, ATI adjusted its asset allocation through acquisition and asset sale. ATI adjusted it allocation of patents

resource in the process of acquisition for three times all together. In 2006, Dynamic

Flowform put forward a metal spinning method for processing a-p titanium alloy

under ordinary temperature in one of its patents, by which it can not only

produce net forming or near-net forming titanium alloy tubing but also reduce

the waste of raw materials and cost.

In another

application of Dynamic Flowform in 2013, which was US847954, the company

proposed a centrifugal casting method for processing seamless pipe. By the

means of acquisition, ATI received the core technologies of the field of metal

spinning of tubing of Dynamic Flowform.

*This article is edited and translated by

CCM. The original version comes from China Invention & Patent.

About

CCM:

CCM is the leading market intelligence

provider for China’s agriculture, chemicals, food & ingredients and life

science markets. Founded in 2001, CCM offers a range of data and content

solutions, from price and trade data to industry newsletters and customized

market research reports. Our clients include Monsanto, DuPont, Shell, Bayer,

and Syngenta. CCM is a brand of Kcomber Inc.

For more information about CCM, please

visit www.cnchemicals.com or get in

touch with us directly by emailing econtact@cnchemicals.com or calling +86-20-37616606.